In recent years, several research studies have proved that the application of GBE could significantly enhance the resistance to intergranular corrosion ( Lehockey, 1997 Shimada, 2002), hot corrosion ( Deepak, 2016), stress corrosion cracking ( Gertsman, 2001 West, 2009), fatigue ( Kobayashi, 2011), creep ( Thaveeprungsriporn, 1997 Spigarelli, 2003), and embrittlement ( Watanabe, 1999). As a result, the properties related to GBs can be greatly improved. The TMP can significantly increase the fraction of the ordered-structure GBs and effectively optimize the grain boundary character distribution (GBCD) ( Li, 2009 Sinha, 2015 Kang, 2021). Thermomechanical processing (TMP) comprising a combination of prior deformation and consequent annealing has been commonly considered as a successful GBE method ( Engelberg, 2008). It is generally considered that material with high frequency of SBs has a high resistance to the intergranular deterioration, especially coherent ∑3 boundaries.

#Grain boundary free

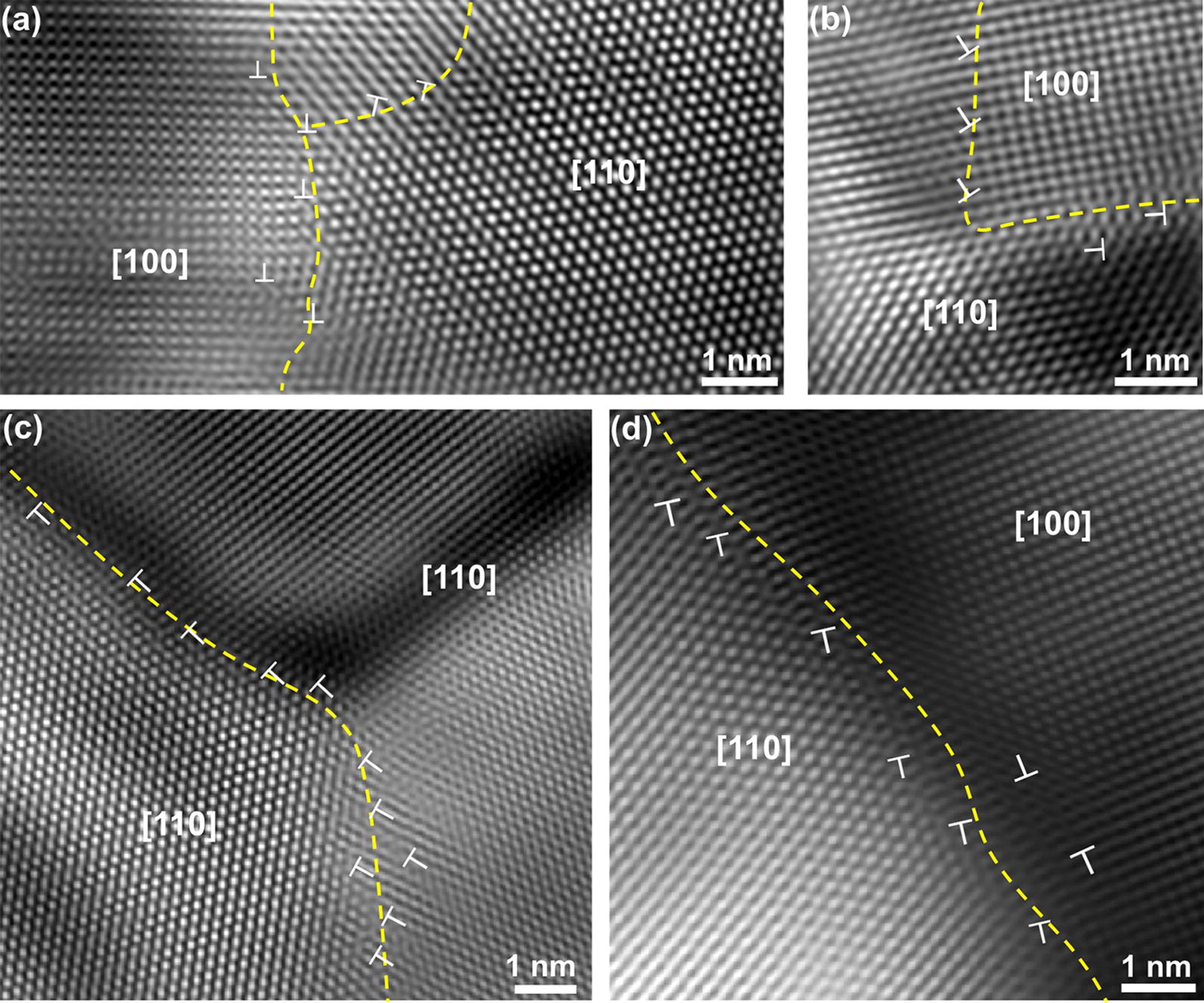

Compared to the RHAGBs, the SBs are usually difficult to be degraded due to their higher ordering degree, closer atomic packing, smaller free volume, and lower interface energies. They are the SBs whose sigma value are ≤ 29 according to the Brandon criterion and others which are random high-angle grain boundaries (RHAGBs). Grain boundaries can be categorized by “sigma value (Σ)” into two families. The structure of grain boundaries has commonly been described by the coincidence site lattice (CSL) model based on the misorientation between the neighboring grains. According to the principle of GBE, the enhancement of grain boundary failure resistance can be attributed to the increase of special boundaries (SBs) and the redistribution of the grain boundary network. Grain boundary engineering (GBE) as an approach of grain boundary design and control was first proposed by Tadao Watanabe (1984). Therefore, the type, the frequency, and the character of the grain boundaries should be optimized to improve the properties of the steel. GB-related cracks always result in the failure of 316L ASS in the corrosive environments. However, the links between the grains of ASS are usually weak. The low-energy special boundaries had strong intergranular corrosion resistance, but the strength of these boundaries was not enough to resist the propagation of transgranular fatigue cracks.ģ16L austenitic stainless steel (ASS) has been widely used in petrochemical, chemical, power, and nuclear industries (Wang, 2019). The highest corrosion fatigue life for 3,187 cycles was obtained when the TMP parameters of the 316L ASS were of 5% strain, annealing temperature of 1,273 K, and annealing time of 45 min. The Σ9 and Σ27 boundaries were generated by the reaction of special boundaries. The results indicated that a high fraction (about 74%) of special boundaries as well as the interrupted network of random high-angle grain boundaries were obtained through 5% strain followed by annealing at 1,273 K for 90 min. The effects of TMP on the GBCD and corrosion fatigue properties in high-temperature and high-pressure water were investigated. Grain boundary engineering (GBE) treatment was performed through thermomechanical processing (TMP) to optimize the grain boundary character distribution (GBCD) of 316L austenitic stainless steel.

0 kommentar(er)

0 kommentar(er)